- Startseite

- 3D Printers and accessoires

- Formenbau & Gießen

- Silikon-Polykondensation

- Silikon-Polyaddition

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound ™ Serie

- Smooth-Sil™ Serie

- Sorta Clear Serie - 'Wasserklare' Silikone

- Body-Double 'Hautsichere' Silikone

- Psycho Paint ™ Silikonfarbe Basis

- Platsil Gel & Deadener

- Rubber Glass

- Encapso™ K

- Solaris ™

- Soma Foama ™ - Silikonweichschaum

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- Silikone Mattierung & Glättungsmittel

- POLYURETHAN KAUTSCHUCK

- Alginat

- POLYURETHAN HARZ

- POLYURETHAN SCHAUM

- Epoxidharz

- Latex & Schaumlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monstermakers Schaumlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Beschichtungs-/Tauchlatex Latex HX-200™

- Holden's HX- Body Latex™ Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Brushable Mold Making Latex HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's HX-Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigmente

- Latex Paint

- Latex Thickener

- Polyester

- Gips & Zement

- AcrylCast

- Prince August

- Modellieren

- Jesmonite Acryl Systeme

- Buddy Rhodes Beton Systeme

- Additive

- Versiegler & Trennmittel

- Pigments

- Jesmonite Pigments

- Pure Pigments

- Ultra Fine Pigments

- SilcPig® Silikonpigmente

- Glow Worm™

- Cryptolyte Pigmente

- Silc Pig™ Electric

- Siltone Silikonpigmente

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key Pigments für Silicone

- Kryolan Flock Faser

- Latex Pigments

- Polyester Pigment

- UVO Pigmente

- SO-Strong Pigmente

- Ignite

- Real Metal Powders 2

- Cast Magic™ Powders

- Faux Metal Powders 2

- Farbe

- Maker Pro Paint™

- Maker Pro Paint™ Metallics

- Maker Pro Paint™ Fluorescent

- Vallejo Acrylfarbe

- Vallego Acrylic Metalfarbe

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint ™ Silikonfarbe Basis

- Latexfarbe

- Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Füllmittel und Veredelung

- Lösungsmittel & Verdünner

- Klebstoffe

- Werkzeuge

- Grime & Maske

- Rubber Mask Grease Paint

- Skin Illustrator Paletten

- Skin Illustrator Liquid

- FleshTone 60ml

- FleshTone 120ml

- Dark FleshTone 60ml

- Dark FleshTone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Gel (Glacierungs Gel)

- Skin Illustrator Glazing Spray (Glacierungs Spray)

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Paletten

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- Tattoo Sheets

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Grime Pinsel

- Old Age Stipple

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Ausrüstung

- Spezial Effekte

- Prosthetische Materialien

- Marken

- FormX Academy

- Anwendungen

- Literatur

Smash Plastic

Smash-Plastic

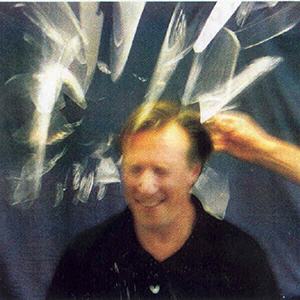

SMASH! Plastic™ ist eine klare flüssige Polyurethan-Kunststoff, der auch als Glas gebrochen werden kann. Das Harz kann in Platten von wenigen Millimetern Dicke gegossen werden. Es wird wie bei einem Glasfenster , aber ohne die Verletzungsgefahr, brechen.

Rotationsformen ermöglicht es hohle Formen wie Flaschen und dergleichen zu gießen. Diese können als zerbrechliche Requisiten genutzt werden. Das Harz ist sehr UV-stabil. Intensive und lebendige Farben können durch Zugabe von verschiedenen Pigmenten erreicht werden.

Technical bulletin Smash Plastic

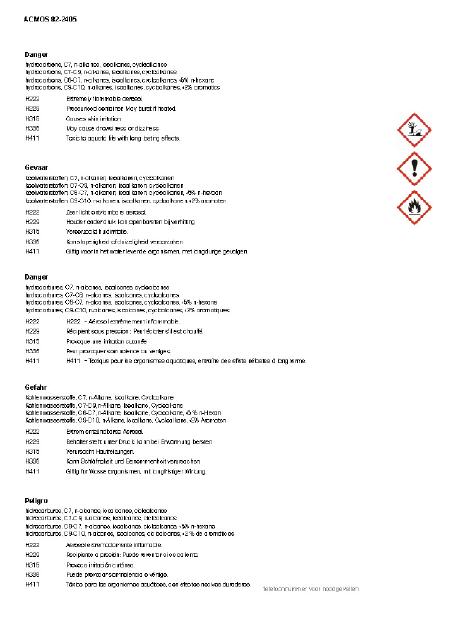

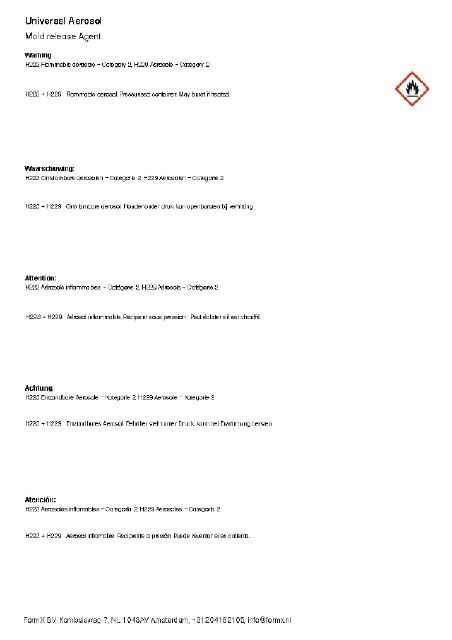

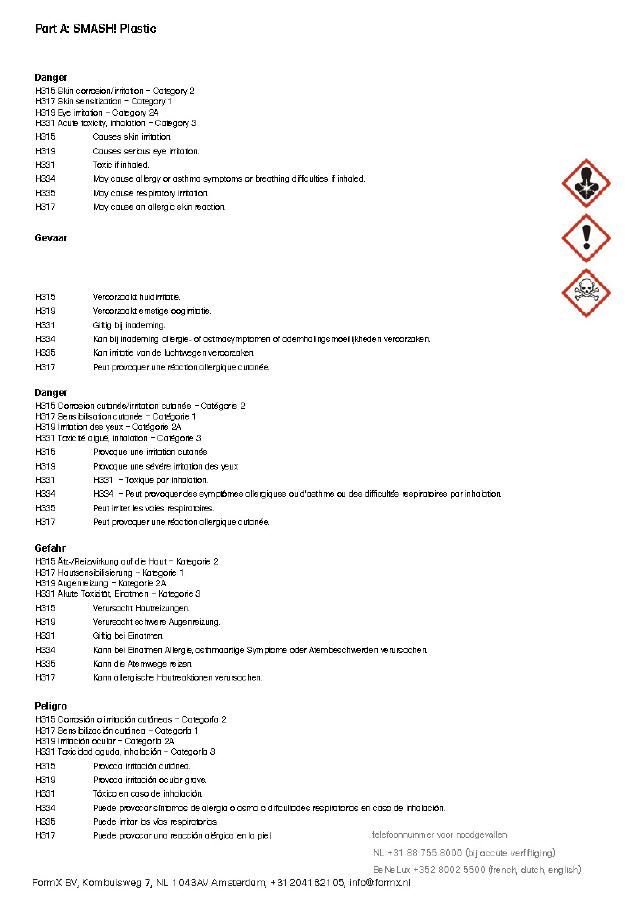

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

Smash Plastic

Selecting A Mold Rubber - Casting into a silicone mold made with Smooth-On Mold Max™ Silicone or Mold Star™ 15, 16 or 30 platinum cured silicone (not Mold Star™ 20T) is recommended. Do not use other silicone products. If you are unsure about surface compatibility, a trial casting should be made. To prevent cure inhibition, post-cure newly made Mold Max™ silicones for 8 hours at 60°C and let cool prior to casting resin.

Measuring - Materials should be stored and used in a warm environment 23°C. This product has a limited shelf life and should be used as soon as possible. The proper mixing ratio is 100A:100B by weight or volume.

Mixing - Dispense equal amounts of Parts A and B into a mixing container and mix thoroughly for 90 seconds, making sure you scrape the sides and bottom of the container several times. If coloring or adding filler, add filler or tint to Part B and pre-mix thoroughly before adding Part A.

If vacuum degassing prior to pouring, subject mixture to 29 h.i.g. mercury in a suitable vacuum chamber for 2 - 3 minutes or until mixture rises, breaks and falls. Allow for 3 to 4 times volume expansion in mixing container. Do not vacuum too long, as this material gels quickly. Apply Universal™ Mold Release to mold surface prior to casting to ensure easy demold of fragile castings.

Curing - Important: Use this product with at least room size ventilation or in proximity to a forced outlet air vent and do not inhale/breath fumes. Fumes, which may be visible with a significant mass concentration, will quickly dissipate with adequate ventilation. Castings with significant mass may be hot to the touch and irritate skin immediately following cure. Let casting cool to room temperature before handling.

Pouring - Do not spill on skin. Pour material in the lowest spot of mold cavity and let material rise and seek its level.

Rotationally Casting - Pour material into mold and rotationally cast for 7 – 10 minutes. Estimating the amount of material you need to build 0.33 cm thickness on your rotationally cast piece may take some practice & experimentation.

Demold - After 90 minutes, plastic is cured enough to be removed from the mold. Plastic is very fragile, so be careful removing your casting from the mold. Applying Universal Mold Release™ to mold surface before casting should aid in removing the casting from your mold. The longer this material cures the more brittle it becomes, reaching full “brittleness” in 24 hours.

Creating a Glossy Surface - Applying a fine mist of denatured alcohol using a sprayer (such as the KWIKEE™ Sprayer) over the surface of a cast SMASH! Plastic™ piece will cause the surface to become glossy/shiny and enhance the glass-like appearance of a breakaway prop. Applying denatured alcohol will cause the surface to become temporarily sticky or tacky. Allow denatured alcohol to dry thoroughly until the surface of the casting is no longer tacky before using prop.

Temperature - When castings are exposed to temperatures above 26°C, they may soften and warp. Store castings at or below room temperature for 24 hours prior to use.

Usage - Inanimate Object: Let material cure for at least six hours prior to “smashing” against inanimate object (for example, on the floor, a wall, etc.).

Usage - On A Person: Before “smashing” a cast piece over someone’s head, make sure that the wall thickness in all directions is not more than 0.33 cm. Also, let the material cure for at least 16 hours at room temperature to become fully “brittle”.

Warning: Smashing a cast piece that is not fully cured or has a wall thickness greater than 1/8” – 0.33 cm against a body part may result in serious physical injury

Messen, Wiegen und Mischen

Pinsel

Sicherheit

Trennmittel

Hilfe bei der Auswahl

Produkte nach Anwendung sortiert, z. B.:Lifecasting, Bildhauerei, Gießen, Special FX Make-up, Zahnprothesen Special FX, Studium.

Ihr One-Stop-Shop für 3D-Modelling-Materialien